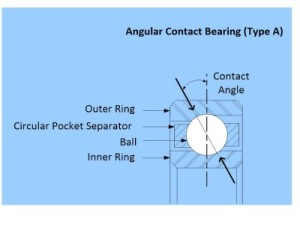

TYPE A: ANGULAR CONTACT BALL BEARING

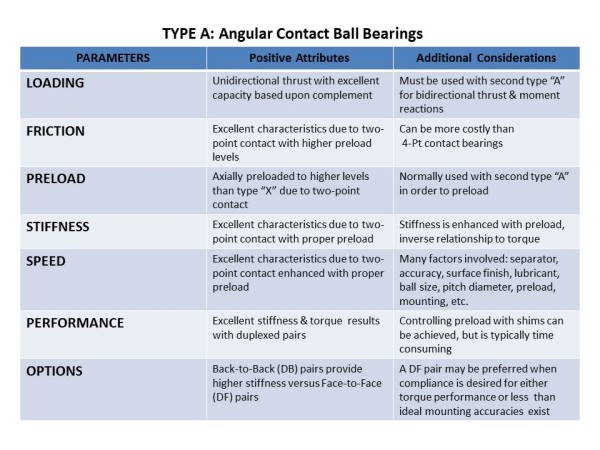

Type A Angular Contact Ball Bearings are uniquely suited for unidirectional axial loads. Angular Contact Bearings should be mounted with two bearings opposed to one another to react bidirectional and reversing thrust loads, radial loads and moment loads.

Type A bearings contain one ring with a counterbore that is snapped over the ball compliment, separator and second ring. This feature allows type A bearings to be assembled with a full compliment of balls without the use of a loading notch. Typically, type A bearings are assembled with a 2/3rds compliment, which is higher than type R and X’s. The additional balls allow for greater load carrying capacity in the axial and radial directions. A pair of angular contact bearings moment loads capability is also enhanced by the ball compliment and as a function of the distance between the two bearing center-lines.

Type A bearings are an excellent choice when high stiffness is desirable in conjunction with low, consistent torque. A pair of Type A bearings maintain two-point contact under normal load conditions and therefore can be preloaded to a higher degree versus a Type X and maintain desirable torque properties.

Type A bearing are often specified as matched sets when they are mounted adjacent or with equal length spacers. Specifying a matched set alleviates the burden of grinding shims to achieve the desired preload during assembly. Duplexed pairs are offered in back-to-back (DB) or face-to-face (DF) configurations.

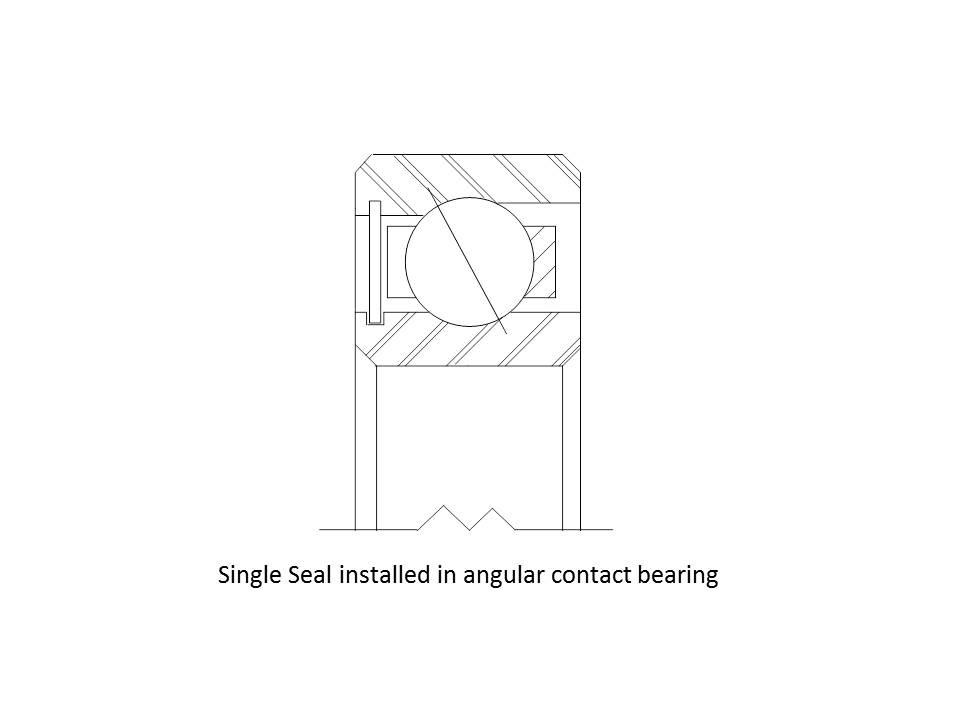

Type A bearings are offered with a standard 30 degree contact angle and either a nylon or brass continuous ring, circular pocket separator. Typically Type A bearings are offered in only an open configuration; however, APG offer most angular contact bearings with single or outboard seals or shields as shown below: